REDUCING RISK WITH NUMERICAL CONTROL

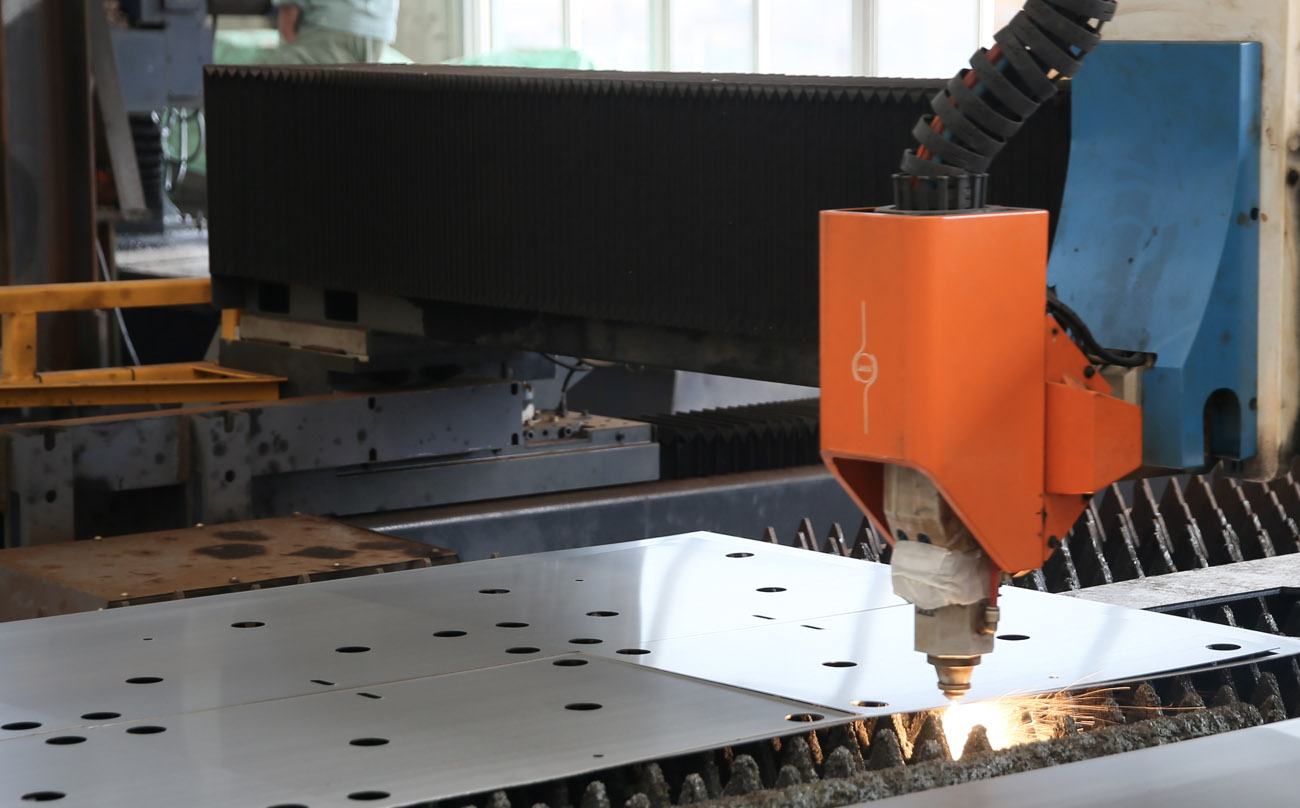

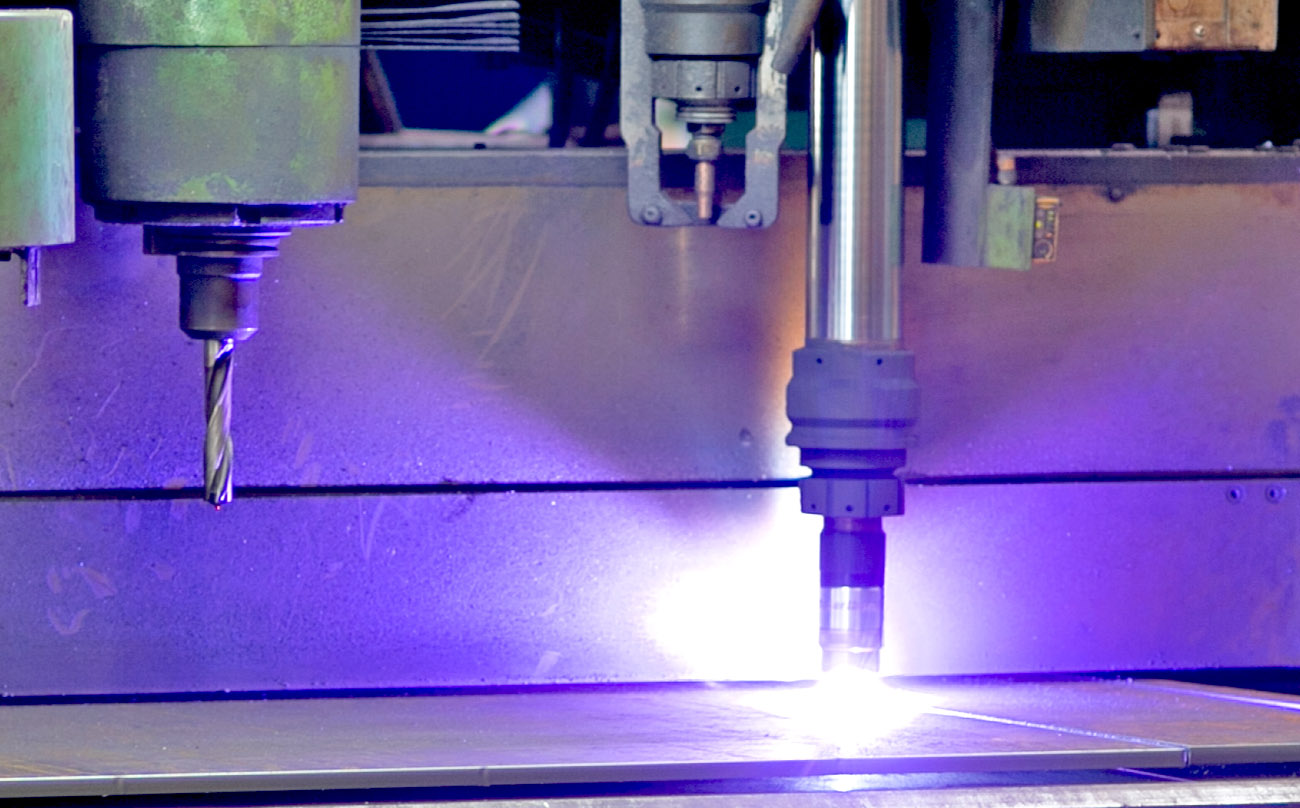

Precision and efficiency are crucial elements in structural steel fabrication that significantly impact project cost and control. For all of the risks undertaken in a project, the need to prevent errors tops the list, along with meeting delivery dates. A small workshop with a couple of fabricators may be able to get away with analog machinery, but any shop intending to replicate procedures in a fast-paced production environment must do so with the assistance of computer numerical control (CNC) machining. CNC machines improve accuracy, consistency, and repeatability, lessening waste and increasing speed. This process reduces the overall operational cost.

The revolution of CNC offers countless tools to increase productivity while improving fabrication accuracy, consistency, and speed. Steel fabrication includes any computer-assisted equipment or machines used to measure, cut, saw, punch, cope, bevel, bend, align, drill, bore, mill, stamp, mark, or weld. Indeed there are more applications, but this will do for now. CNC machinery is software-driven, allowing operators to use manual commands and 1:1 numerical ratio control (NC) files prepared by the detailers. Using NC files allows for precise and accurate movement of the cutting tools, resulting in parts that meet exact specifications.

MORE STORIES

MMEC Modular is providing original equipment fabrication and construction of air-cooled condenser modules and related commodities.

Modern Group ramps up output of mining commodities as more than 70 countries, and a range of industries pledge net-zero emissions.

Modern Group has shipped over 100 Heat Recovery Steam Generators into the global energy sector. Let's take a closer look.

MMEC production teams were on target to meet the first delivery milestone for the Kemerton Lithium Hydroxide Project.

Modern Group managers received two Supplier Quality Excellence Awards at Valmet's Supplier Day in Shanghai, China.

CNC machine accuracy is a must-have component in today's workshops. A great fabricator must try to balance it, but cannot do without it.

Senior Project Manager Ivy Cheng performs a parenting juggling act, trying to separate the ABCs from Packing Lists.

The M/V Chipolbrok Atlantic loads chemical pipe racks and process modules before setting sail for the Panama Canal and the Gulf of Mexico.

Modern Group undertakes a wide range of classroom and on-the-job HSE training to demonstrate and communicate safety culture.

Bechtel staff and MMEC management happily celebrate the first-cutting ceremony of steel for Woodside Energy’s Pluto LNG Train 2.

Guan Yan An overcame hardship and challenges in the countryside of Lianyungang to find his way in life and that of his two sons.

Modern Group signs a significant contract to supply onshore LNG facility steel structures for the Qatargas North Field Expansion (NFE) Project.

.png)